Here at GYW Solutions our expert knowledge is based on over 15 years of experience working within various kinds of cold storage designing, constructing, installing, and maintenance. Combined with our hard-working and highly skilled team, you can be sure the cold storage solution we provide will be sure to fit the bill. Our client’s feedback is our main medium for advertising our business. We always ensure customer satisfaction. Our services are affordable and competitive. Apart from designing and building a cost-effective cold room, they are other reasons we are among theleading companies in the country.

Core technological advantages:

Focusing on the pain points of the cold chain industry, the company innovatively creates an “Al intelligent integrated cold storage cold source” solution, which completely solves the problems of “component mismatch, pipelinedesign defects, large temperature difference operation, high energy consumption, and data loss” that exist in traditional cold storage. On the premise of ensuring the temperature and humidity of the cold storage. it has “super largecold storage towing capacity”. Achieve breakthroughs in four maior industries:

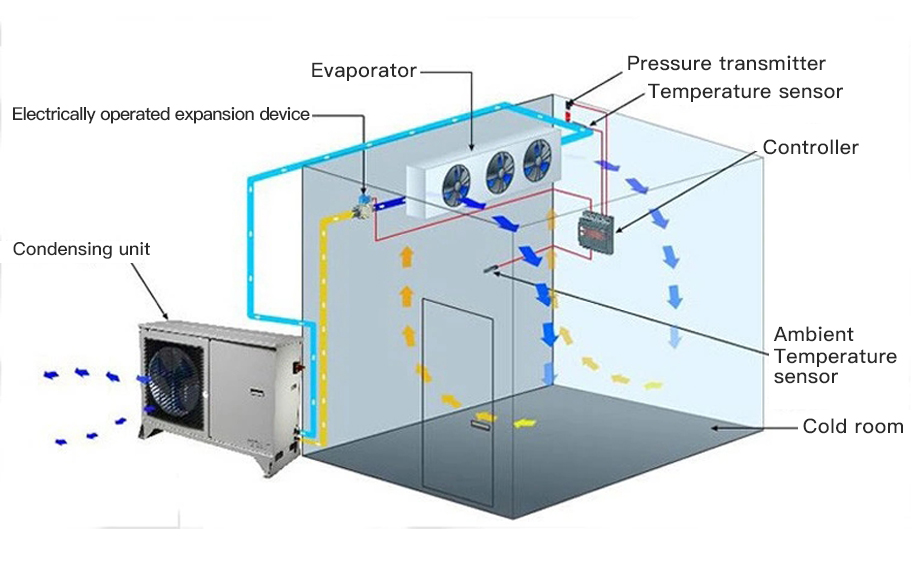

»Standardized integration: Innovative modular design of refrigeration equipment, compatible with medium/high/low temperature units, achieving seamless integration of cold sources, cold capacity air coolers, and lo’T controlsystems.

»Energy Efficiency Revolution: Based on the collaborative innovative design of the complete cold storage coldsource system, the integration of precise control of fluid valves and standardized pipeline installation processesis achieved through the three in one technology The system’s COP has been improved by 30%, the cooling temperature difference has been reduced by 15%, and the comprehensive energy consumption has been reduced by 35%.restructuring the cold chain industry to become a new benchmark for energy conservation.

»Safety redundaney: The design of an independent refrigeration cyele system avoids the risk of systematic par.alysis caused by single point failures in traditional parallel units, and improves the safety of cold storage by morethan 50%.

»Data empowerment: Build a device lifecycle database, end the “product without data” situation, support preciseoperation and intelligent decision-making.

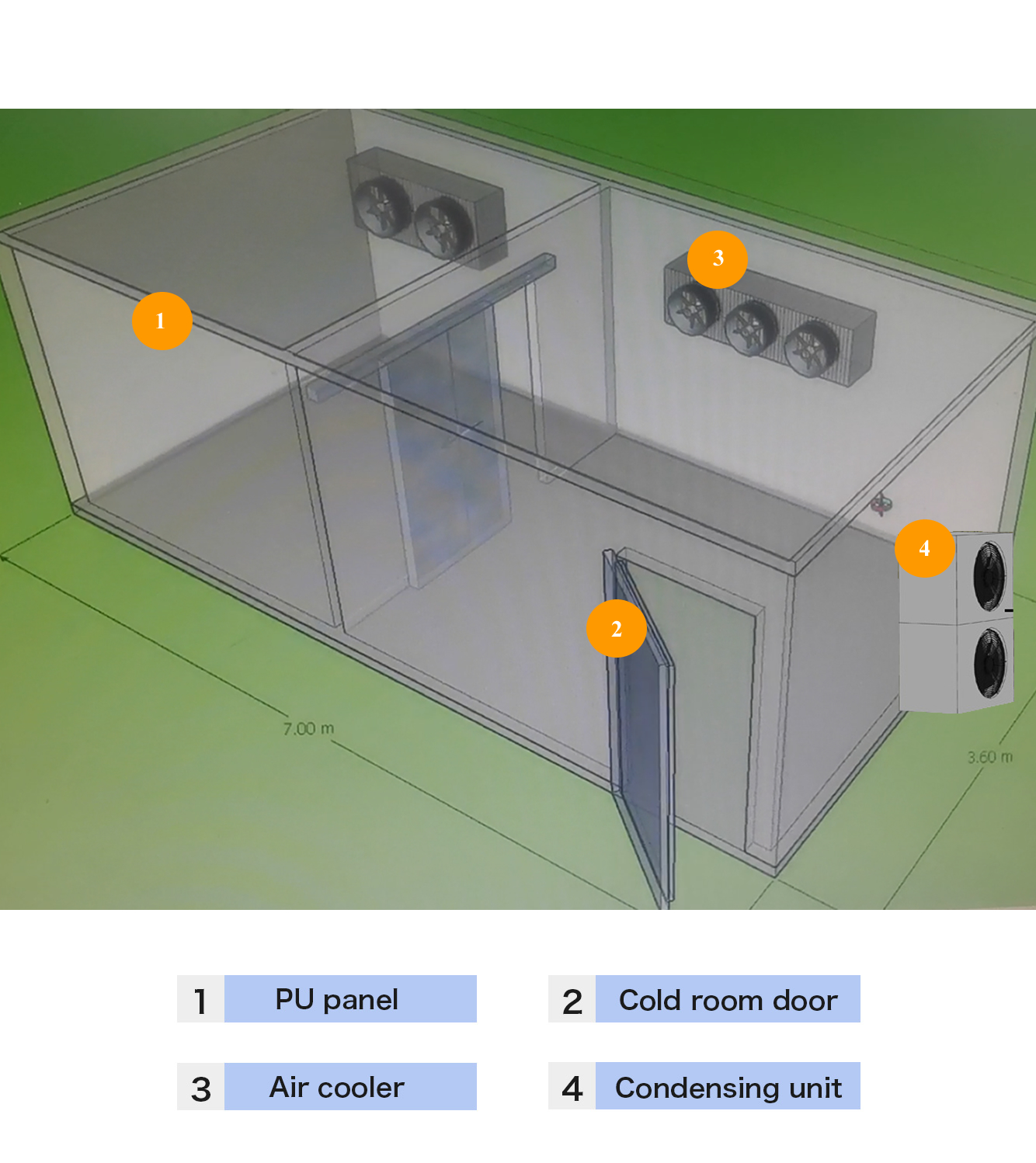

1、The four main products for building a cold storage are as follows:

2、Cold storage design drawings:

AI Intelligent Data Analysis Platform:

3、Detailed Introduction:

Meat seafood ice cream storage room Parameter

| Dimension | Customized length, width, height | ||

| Refrigeration unit | Carrier/Bitzer/Copeland etc. | ||

| Refrigeration type | Air cooled/water cooled/evaporation cooled | ||

| Refrigeration | R22,R404a,R447a,R448a,R449a,R507a Refrigerant | ||

| Defrost Type | Electric defrosting | ||

| Voltage | 220V/50Hz,220V/60Hz,380V/50Hz,380V/60Hz,440V/60Hz optional | ||

| Panel | New material polyurethane insulation panel,43kg/m3 | ||

| Panel thickness | 180mm 200mm | ||

| Type of door | Hanged door,sliding door,double swing electric sliding door,truck door | ||

| Temp. of room | -30~-40℃ optional | ||

| Functions | chicken,dumplings, meat, ice cream, fish, seafood ,etc. | ||

| Fittings | All necessary fittings are included,optional | ||

| Place to assemble | Indoor/out door(concrete construction building/steel construction building) | ||

Cold room structure:

Cold room applications:

In food industry, cold room is usually used in food process factory, slaughterhouse, fruit and vegetable

warehouse,supermarket,hotel, restaurant, etc.

In medical industry, cold room is usually used in hospital, pharmaceutical factory, blood center, gene center, etc.

Other related industries, such as chemical factory, laboratory, logistics center, they also need cold room.

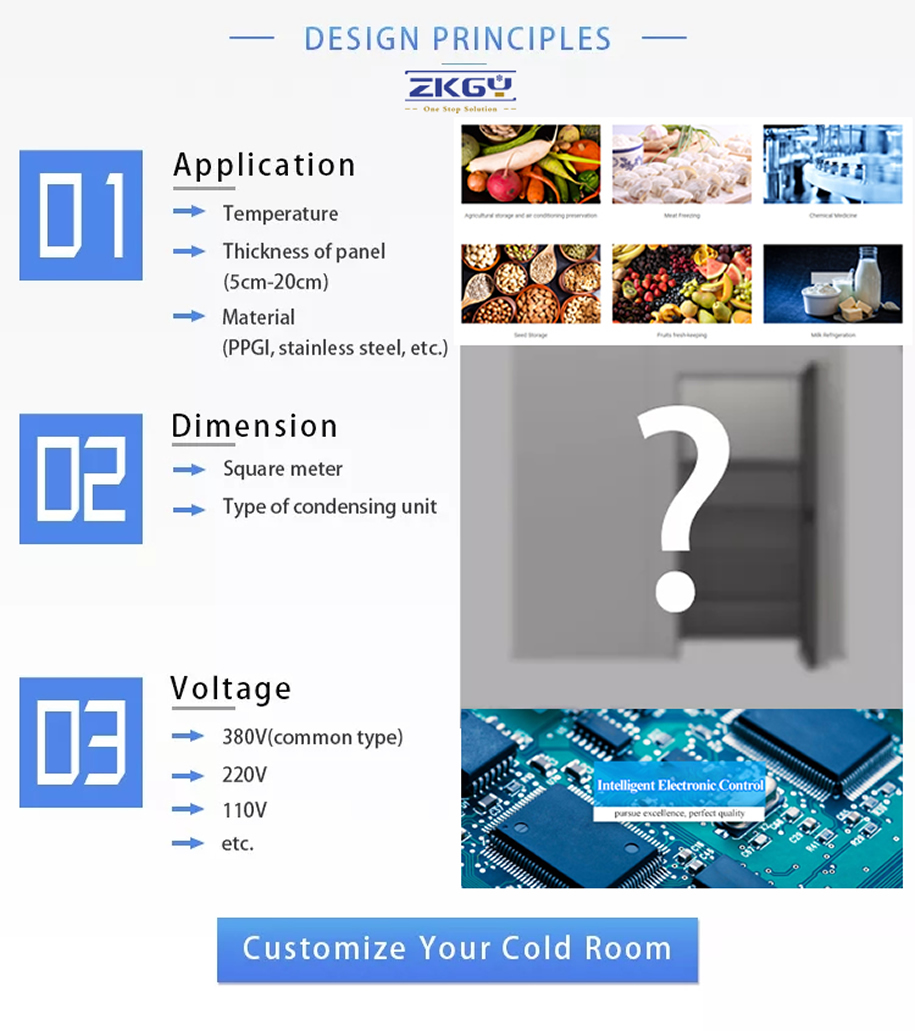

Design principle

For cold room projects, the following factors should be fully considered:

|

Application for example

|

Room Temperature

|

||

|

Fruit & Vegetable

|

-5 to 10 ℃

|

||

|

Chemical factory,medicine

|

0 to 5 ℃

|

||

|

Ice cream, ice storage room

|

-10 to -5 ℃

|

||

|

Frozen meat storage

|

-25 to -18 ℃

|

||

|

Fresh meat storage

|

-40 to -30 ℃

|

|

General details of fresh cold room

|

||||

|

Reference dimension(L*W*H)

|

6m*4m*2.5m

|

8m*5m*2.5m

|

10m*6m*2.5m

|

11m*6m*3m

|

|

Application

|

Usually for storage of fresh vegetables and fruits

|

|||

|

Temperature

|

-5°C ~ +5°C

|

|||

|

Power

|

380V/50HZ/3Phase(can be customized)

|

|||

|

Cold room structure

|

||||

|

Surface metal (Take PPGI on both sides for example)

|

0.326mm PPGI

|

0.326mm PPGI

|

0.326mm PPGI

|

0.326mm PPGI

|

|

Thickness of PU panel

|

100mm

|

100mm

|

100mm

|

100mm

|

|

Cold room door(W*H)

|

Hinged door 0.8m*1.8m

|

Hinged door 0.8m*1.8m

|

Manual sliding door 1.5m*2m

|

Manual sliding door 1.8m*2m

|

|

Refrigeration Equipment

|

||||

|

Compressor brand

|

Bitzer

|

Bitzer

|

Bitzer

|

Bitzer

|

|

Compressor type

|

Semi-hermetic

|

Semi-hermetic

|

Semi-hermetic

|

Semi-hermetic

|

|

Compressor model

|

4FES-5Y

|

4DES-7Y

|

4VES-10Y

|

4PES-15Y

|

|

Refrigerant

|

R404a

|

R404a

|

R404a

|

R404a

|

|

Condenser model

|

FNH-12.5/41

|

FNH-17/60

|

FNH-23/80

|

FNH-35/120

|

|

Evaporator model

|

DD-30

|

DD-60

|

DD-80

|

DD-120

|

|

General details of freezer cold room

|

||||

|

Reference dimension(L*W*H)

|

4m*4m*2.5m

|

6m*4m*2.5m

|

6m*6m*2.5m

|

6m*8m*2.5m

|

|

Application

|

Usually for storage of frozen fish, meat and seafood

|

|||

|

Temperature

|

-20°C ~ -18°C

|

|||

|

Power

|

380V/50HZ/3Phase(can be customized)

|

|||

|

Cold room structure

|

||||

|

Surface metal (Take PPGI on both sides for example)

|

0.326mm PPGI

|

0.326mm PPGI

|

0.326mm PPGI

|

0.326mm PPGI

|

|

Thickness of PU panel

|

150mm

|

150mm

|

150mm

|

150mm

|

|

Cold room door(W*H)

|

Hinged door 0.8m*1.8m

|

Hinged door 0.8m*1.8m

|

Manual sliding door 1.5m*2m

|

Manual sliding door 1.5m*2m

|

|

Refrigeration Equipment

|

||||

|

Compressor brand

|

Bitzer

|

Bitzer

|

Bitzer

|

Bitzer

|

|

Compressor type

|

Semi-hermetic

|

Semi-hermetic

|

Semi-hermetic

|

Semi-hermetic

|

|

Compressor model

|

4DES-5Y

|

4TES-9Y

|

4PES-12Y

|

4HE-18Y

|

|

Refrigerant

|

R404a

|

R404a

|

R404a

|

R404a

|

|

Condenser model

|

FNH-12.5/41

|

FNH-17/60

|

FNH-23/80

|

FNH-35/140

|

|

Evaporator model

|

DD-30

|

DD-60

|

DD-100

|

DD-140

|

|

Parameter

|

|||

|

Brand

|

CASGYW or OEM / ODM

|

||

|

Size

|

Customized

|

||

|

Temperature

|

-50°C to 50 °C

|

||

|

Voltage

|

380V, 220V or Customized

|

||

|

Main parts

|

Polyurethane(PU) sandwich panel

|

||

|

Cold room door

|

|||

|

Condensing unit——German Bitzer, American Emerson, GREE, etc.

|

|||

|

Air cooler——ZKGY,EDEN, etc.

|

|||

|

Fittings

|

Valves, copper pipe, thermal insulation pipe, wire, PVC pipe for wire, PVC door curtain for sliding door, LED light, switch,electrode, insulating tape, belting, etc.

|

||

|

Certification

|

ISO9001:2015, BV, SGS, TÜV

|

||

|

Cold room panelWe use fluoride-free material, it is more environment-friendly. Our cold room panels can reach fireproof level B2.

Polyurethane panel is foamed by high pressure with density of 38-42 kg/m3. So the thermal insulation will be good.

|

|

Cold room door

We have different types of cold room door, such as hinged door, sliding door, free door and other types of doors according to your requirement. |

|

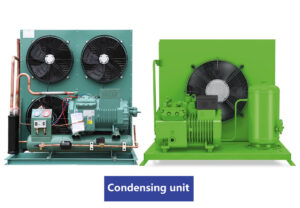

Condensing unitWe use the world famous compressor like German Bitzer, American

Emerson, etc.

It is easy to operate the automatic high-precision digital controller with high efficiency.

|

|

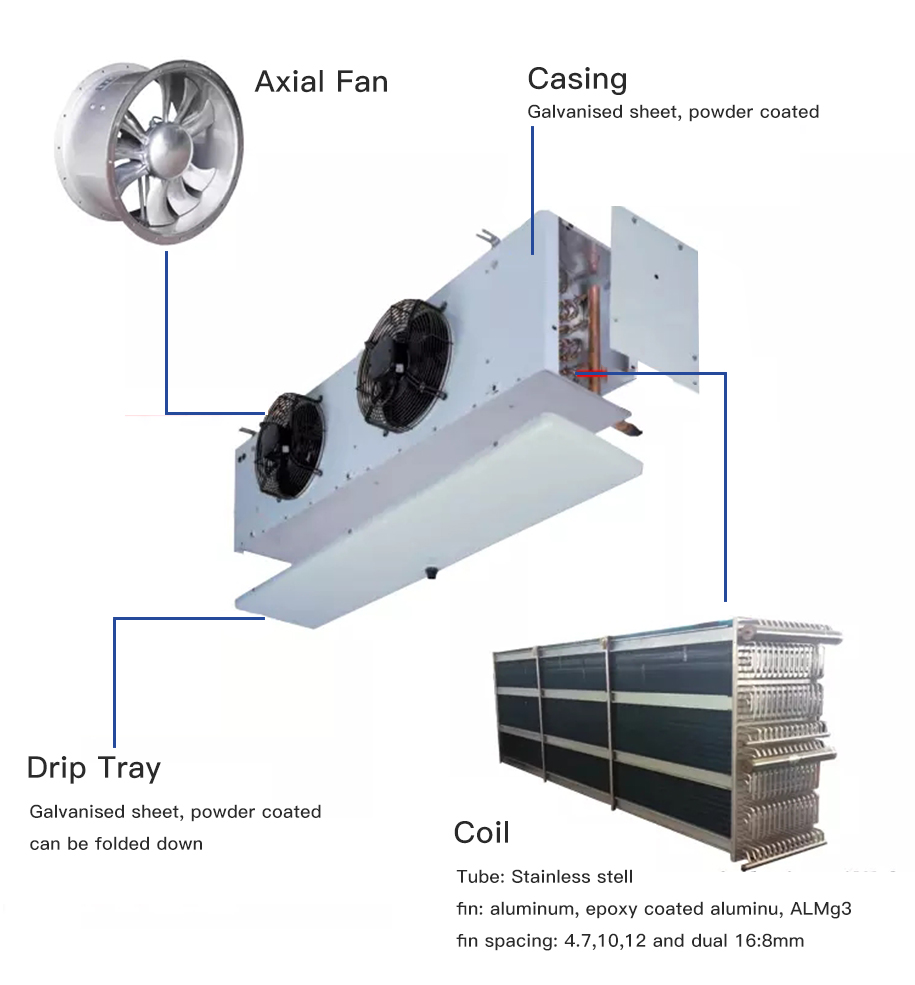

Evaporator(Air cooler)————————————————————————————————————————————————— Model: DD series, DJ series, DL series.

DD series is suitable for medium temperature;

DJ series is suitable for low temperature;

DL series is suitable for high temperature.

|

|

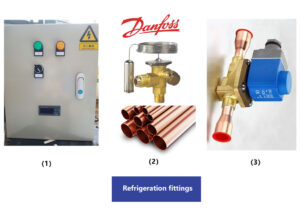

Refrigeration fittings————————————————————————————————————————————————— (1)Temperature controller

Famous brand: Italy Dixell with DELIXI or Korean LG, French Schneider

(2)Valve Parts

Famous brand: Denmark Danfoss

(3)Copper pipe and connection

(4)Thermal insulation pipe, wire, PVC pipe, PVC door curtain for sliding door,

LED light, switch, electrode, insulating tape, belting, etc.

|

How to Installation:

Step 2: Wall panel

Step 3: Ceiling panel

Panels will be marked according to drawing and connected by cam locks, you just need to lock different panels together, then seal them with sealant to keep sealed.

You can watch this following video about how to install cold room.

Reviews

There are no reviews yet.